Bespoke automated control systems and user-friendly HMI tailored to your requirements.

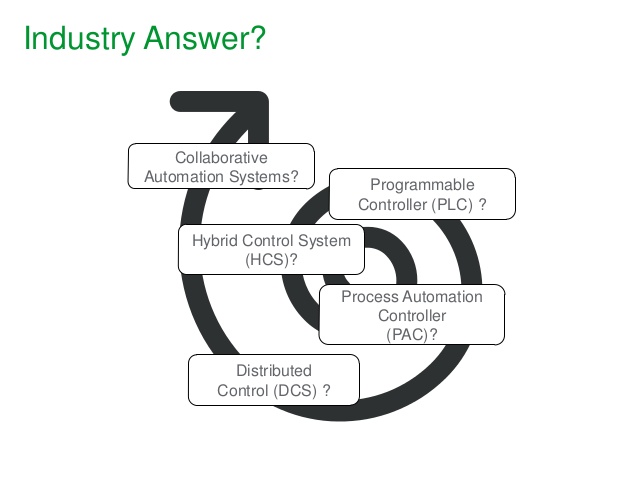

Traditionally, DCS-systems have been used primarily in process industries, while PLC's are more popular in industries like electronics or automotive. Batch industries on the other hand opt for both DCS and SCADA and PLC. How can you make the correct choice?

The PLC and the DCS each have their ‘sweet spots’ where they are optimized to deliver the best possible results. And many companies make full advantage of their capabilities, combining both systems to cover all the upstream and downstream bases in their production process. Some end users have an entire system of ‘integrated’ elements, sometimes forced to work together, with varying results.

What they could do is run a single, hybrid control strategy that combines the benefits of both DCS and PLC/HMI, enabling them to run completely different processes from the same controller environment.

The advantages of DCS and SCADA/PLC without the history limitations

Advances in technology have allowed companies in the process industries to combine the advantages of DCS and SCADA/PLC without the history limitations tied to each of those options. They can have the global data access, function blocks and inherent redundancy of a DCS system with the speed, scalability and openness of a SCADA/PLC solution, all at a competitive price.

Today’s hybrid systems offer a viable alternative for DCS’s, although the final decision will often depend on more than mere technical parameters...